Her Majesty's DBS Restoration Update: Suspension

Gebruder Gumbold

San FranciscoPosts: 549MI6 Agent

Gebruder Gumbold

San FranciscoPosts: 549MI6 Agent

My Dear Friends in Bond,

The DBS rear suspension and hypoid final drive, with its inboard brakes are all in.

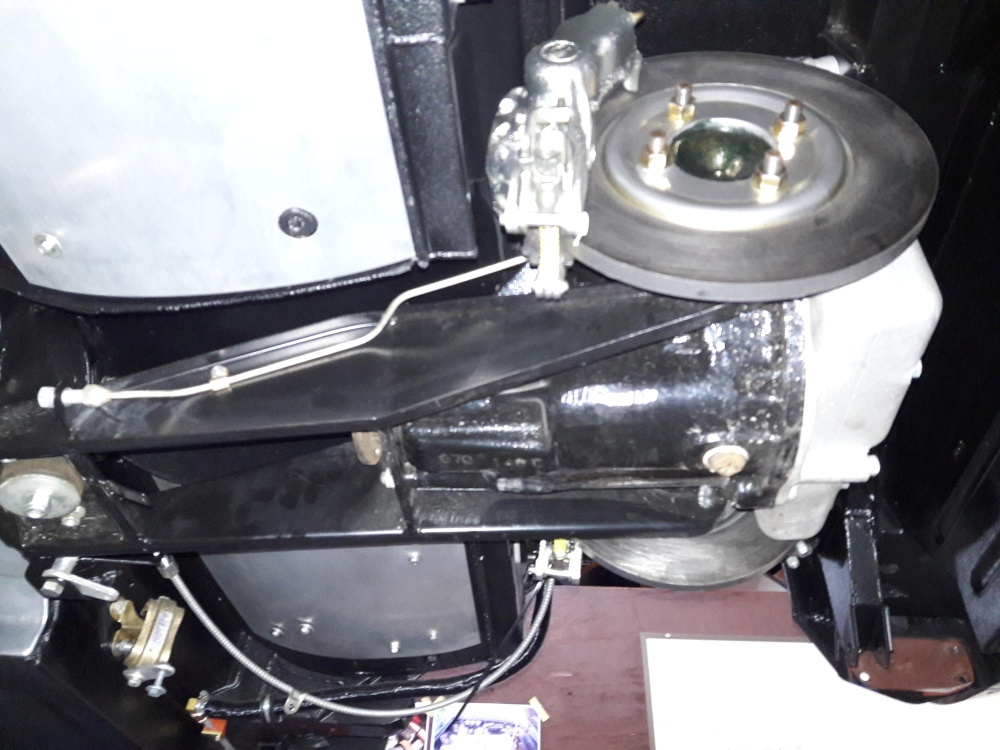

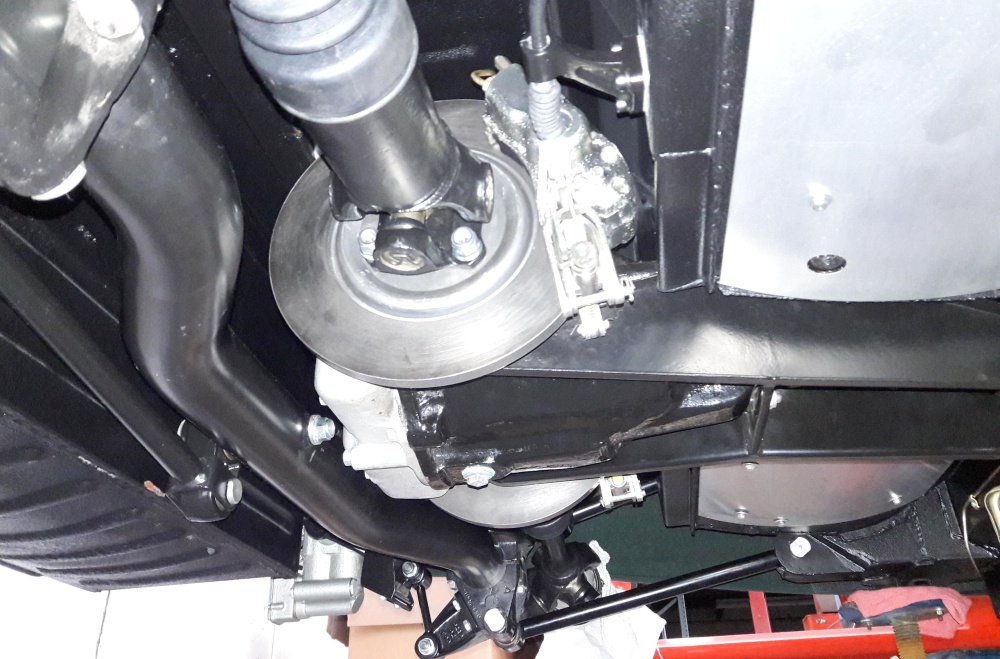

Building the final drive unit. The inboard brakes save unsprung weight and were a feature found also on the Jaguar E-Type, which designer Ken Adam owned. Bond nearly was put into a Jaguar for Goldfinger, but thankfully Guy Hamilton was adamant about the Aston Martin. V8 versions use exactly the same final drive unit, but with vented rear rotors.

Ready to be joined with the mother ship...

With the aid of a transmission jack, which has a foot operated pedal and slant mechanism, up she goes into the chassis pocket and is secured on the mounts.

Setting the pinion angle here. Critical step oft overlooked. Not a bolt up and go process, by any means. Rear mounts have slots and front mount takes shims to accomplish the correct angle. You can just see some of my reference photos on the wall. Yes, I hum the OHMSS music whilst working...

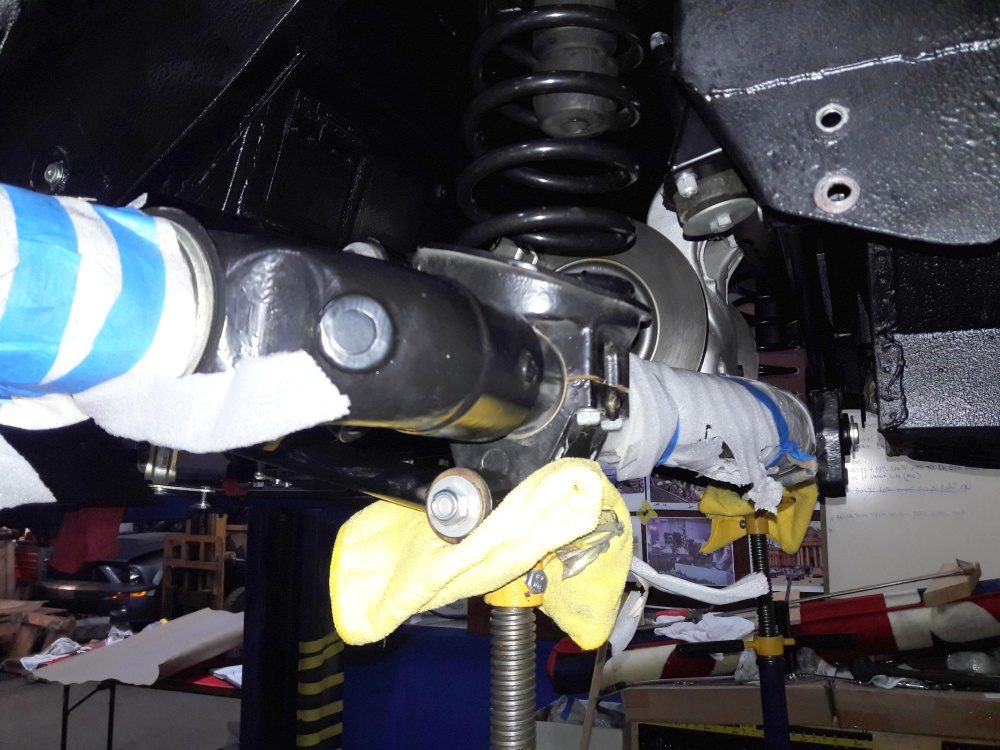

The deDion rear axle is now installed. A ton of shop equipment is needed, including 2 long screw jacks, the transmission stand, wooden blocks, pry bars, and 2 men. Previous Aston Martin models utilised the live solid axle, and this was quite a feat of engineering for the new DBS model to have used. There exists one prototype DB5 with the deDion and a V8 engine, and that would have been the ultimate Aston Martin if it went into production. The roadholding of the DBS is superior to previous models because of this very good rear suspension.

...And there you have it! Control arms and rear Watts linkage- used to keep the rear axle from side to side motion during cornering. I preloaded the control arms using the screw jacks and tightened to factory specifications. Note the large roller splined drive axles- string enough to take 700 horsepower. You can see the handbrake mechanism in the top photo, as well as the exhaust shields on both sides for the twin exhausts.

The large glassfibre air ducting to cool the rear brakes. The large U-Joints are visible here as well.

...And now she's a roller! The spare set of wheels are on loan from Grace Slick's old DBS, and they had been sitting in a barn for over 20 years. I gave them a good clean, and had my tyre chaps mount any old used 15" tyres on them just to roll about the shop, whilst my original Dunlops have been crated up and shipped out for restoration. Note the hexagonal wheel spinners, which were fitted to German and US models, as the triple eared spinners were considered to be too dangerous. Ridiculous! Imagine how beautiful cars would have continued to be without the hysterical Ralph Naders of the world....

A look back in time to how the suspension was when I brought here home in 2008.

....And today. Bit of a difference, wouldn't you say? Angle iron is to lock the steering for rolling back and forth on and off the lift.

Removing the Avon Turbospeed tyres and crating up the Dunlop 15x6 72 spoke wheels for restoration. Will be 22 weeks and over $1000 per wheel (5), plus around $700 freight one way. I generally don't like to talk money with a restoration, but this gives my readers an idea of what the realities of restoration on hand built Aston Martins are. Who needs to buy groceries anyway...

Just for fun, here's the engine and gearbox unit going into my customer's DB6. Essentially the same engine and gearbox as the DBS, although Her Majesty's DBS is fitted with the Vantage engine, which utilises Weber carburettors. She is a 1967 LHD model, originally shipped to France. The car was purchased with most of the parts in boxes, and as of this writing, she is running and driving round San Francisco on nice Sundays. Engine pulls very well, and the gearbox, suspension, and brakes work a treat. Black interior and SU carburettors (Standard engine) producing around 282 BHP, same as the DB5 of Goldfinger. This engine has a 4,2 litre conversion, and feels very strong. I suppose that this is the Aston that Bond would have driven had the 1967 film been in Europe. In 1968, Peter Hunt visited Aston Martin and spied the new DBS model- a sleek departure from the Italian Superleggera body style that began with the DB4, desegno di Touring. The gorgeous new DBS was penned by Scotsman William Towns, all in house at Aston Martin. 2 DBS prototypes, built on widened DB6 chassis, were built by Touring just prior to their closure. The 2 prototypes were quite attractive, although dated in their styling, but are highly sought after collectibles today. Thank Heaven that Bond wasn't in one of those for the OHMSS film, as they are well out of reach for 99% of the enthusiasts and collectors. Peter Hunt said of the DBS "A sleek new Aston Martin for a sleek new Bond!" And that, Lazenby was.

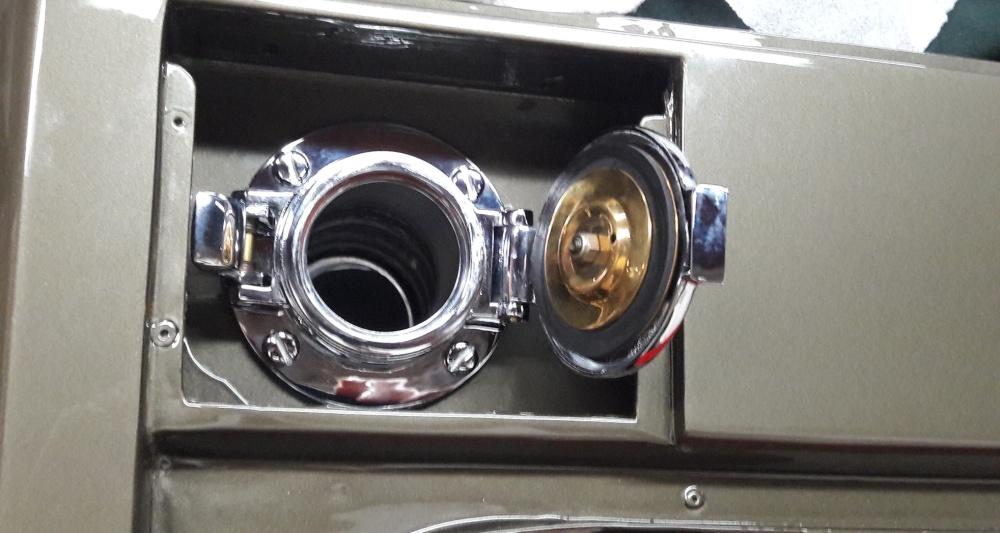

The Monza type fuel fillers go in next. I have fitted a lightweight aluminum fuel tank, as my original steel one had rotted, and the weight savings is incredible. I fitted the new tank using one hand! DBS owners know very well to keep the boot lid closed whilst the filler cap is open, or there shall be a small divot in the boot lid. Twin fillers mean no waiting at petrol pumps!

So much still to do, and the clock keeps ticking twords the San Francisco Auto Show in November...

I do so appreciate all of the great feedback and comments. Hope to have another update soon. The battery and cables go in next, and I shall be living in the boot, ala Goodnight, to complete the plumbing of the fuel system and large amounts of wiring. Outer SS trims are coming back now from polish, so I hope to fit them and take some photos. Very slow going at this stage. There is also the engine to start on the run stand, after reassembly of the leaky water pump and refinish of the exhaust manifolds.

All the best,

Tom

Comments

Wow Tom, it looks amazing. Will you be adding the telescopic sight into glove box 😂

Already done!

🥳

Thanks for the latest update Tom. Really starting to come together - literally!

Is the big unveil in November? Judging by the lead time on the tyres, I guess the wheels will be the final piece in the puzzle to fit?

Thank you all.

Struggling to have her debut at the San Francisco Auto Show....

....However, the restoration of any classic car, especially a hand built Aston Martin cannot be estimated in terms of time or money. I'm up against my trimmer, platers, chrome platers, metal guru, and parts availability. A simple item such as the Satin Trim Paint that I used all over the car is on national backorder, and I only have a couple of cans left. Went to fit the newly rebuilt water pump onto my engine yesterday, as the engine is on a run stand, and it leaked. Will try to bed in the seal by running her later this week. Those are just examples of the many elements and hurdles that one experiences with these projects. I still don't have a back bumper nor back window. Playing the waiting game, but the clock is ticking...

If any of you watch these "Restoration" shows on television, you may think that 6 guys swarming over a car produces a finished product in a 1 hour segment. All nonsense! I have seen 2 of these supposedly "Rescued" cars, and the paint peels off within 6 months! Tis a slow process, not to be rushed.

Thank you all for the kind words of support, and when she is up and running, I should be taking some videos and doing a nice unveil for my AJB brethren.

Cheers, Tom

@Gebruder Gumbold : Looking forward to seeing the videos when you are finished.